Level sensors and Flow meters for the Pharmaceutical Industry.

Level and Flow monitoring for the Pharmaceutical industry

Why is level measurement in the Pharmaceutical industry important?

Level sensors take on an essential role in the pharmaceutical industry. Level monitoring directly influences the quality of medical products and even determines whether the production can go smoothly. Qualified level sensors can help to guarantee the quality of raw materials, semi-finished products, and end products. So, achieving accurate and reliable results is essential.

What about flow measurement?

The monitoring of liquids flowing through pipes gives early warnings of blockages in the process. Accurate flow measurement helps to improve overall running costs, emissions, and the quality of the product. Non-contacting flow meters eliminate the need for maintenance while maintaining the quality of the product without actually coming into contact with the medium.

Why choose Pulsar Measurement?

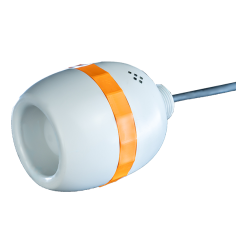

At Pulsar Measurement, we have a wide range of options, including ATEX certified, contacting, and non-contacting solutions. In the Pharmaceutical industry, non-contacting is an ideal solution to help ensure the highest possible quality of the product.

You can view a range of suggested Pulsar Measurement products below:

Product Configurator

The Pulsar Measurement product configurator allows you to select the applications specific to you and discover the most appropriate solutions for your requirements.