The Best of Both Technologies - Radar and Ultrasonic

Radar and Ultrasonic.

The Best of Both Technologies.

There is a place for both ultrasonic and radar technologies in the wastewater, industrial, and environmental markets. Pulsar Measurement delivers complete solutions to provide the right technology that is best for your application. Here you'll find a complete breakdown of both so you can make the choice which suits your needs best!

Radar and Ultrasonic.

The Best of Both Technologies.

There is a place for both ultrasonic and radar technologies

in the wastewater, industrial, and environmental markets.

Pulsar Measurement delivers complete solutions to provide

the right technology that is best for your application. Here you'll find a complete breakdown of both so you can make the choice which suits your needs best!

Radar and Ultrasonic.

The Best of Both Technologies.

There is a place for both ultrasonic and radar technologies

in the wastewater, industrial, and environmental markets.

Pulsar Measurement delivers complete solutions to provide

the right technology that is best for your application. Here you'll find a complete breakdown of both so you can make the choice which suits your needs best!

Radar and Ultrasonic.

The Best of Both Technologies.

There is a place for both ultrasonic and radar technologies

in the wastewater, industrial, and environmental markets.

Pulsar Measurement delivers complete solutions to provide

the right technology that is best for your application. Here you'll find a complete breakdown of both so you can make the choice which suits your needs best!

Radar and Ultrasonic.

The Best of Both Technologies.

There is a place for both ultrasonic and radar technologies

in the wastewater, industrial, and environmental markets.

Pulsar Measurement delivers complete solutions to provide

the right technology that is best for your application. Here you'll find a complete breakdown of both so you can make the choice which suits your needs best!

Pulsar Measurement - We're experts in both

We know that there are other manufacturers out there that will tell you different things about Ultrasonic and Radar technology. No doubt you've heard things like "Radar is the better Ultrasonic" and "Radar is the future", well we're here to bust those myths because it's just not true! At Pulsar Measurement we believe both technologies have their place in the market and choosing the correct technology depends on your application requirements!

We pride ourselves on being experts in both ultrasonic and radar technology, and have a wide range of sensors and options to suit your needs. All of our sensors come with intrinsically safe options, so you can be sure that the sensors you choose can be safely installed in hazardous locations. We offer worldwide support, both remotely and on-site, so whatever your question, please do not hesitate to give one of our friendly service teams a call.

Below you'll find a breakdown of both technologies to help better your understanding and ultimately, giving you the knowledge you need to make the best choice for your application!

Pulsar Measurement - We're experts in both

We know that there are other manufacturers out there that will tell you different things about Ultrasonic and Radar technology. No doubt you've heard things like "Radar is the better Ultrasonic" and "Radar is the future", well we're here to bust those myths because it's just not true! At Pulsar Measurement we believe both technologies have their place in the market and choosing the correct technology depends on your application requirements!

We pride ourselves on being experts in both ultrasonic and radar technology, and have a wide range of sensors and options to suit your needs. All of our sensors come with intrinsically safe options, so you can be sure that the sensors you choose can be safely installed in hazardous locations. We offer worldwide support, both remotely and on-site, so whatever your question, please do not hesitate to give one of our friendly service teams a call.

Below you'll find a breakdown of both technologies to help better your understanding and ultimately, giving you the knowledge you need to make the best choice for your application!

Pulsar Measurement - We're experts in both

We know that there are other manufacturers out there that will tell you different things about Ultrasonic and Radar technology. No doubt you've heard things like "Radar is the better Ultrasonic" and "Radar is the future", well we're here to bust those myths because it's just not true! At Pulsar Measurement we believe both technologies have their place in the market and choosing the correct technology depends on your application requirements!

We pride ourselves on being experts in both ultrasonic and radar technology, and have a wide range of sensors and options to suit your needs. All of our sensors come with intrinsically safe options, so you can be sure that the sensors you choose can be safely installed in hazardous locations. We offer worldwide support, both remotely and on-site, so whatever your question, please do not hesitate to give one of our friendly service teams a call.

Below you'll find a breakdown of both technologies to help better your understanding and ultimately, giving you the knowledge you need to make the best choice for your application!

Pulsar Measurement - We're experts in both

We know that there are other manufacturers out there that will tell you different things about Ultrasonic and Radar technology. No doubt you've heard things like "Radar is the better Ultrasonic" and "Radar is the future", well we're here to bust those myths because it's just not true! At Pulsar Measurement we believe both technologies have their place in the market and choosing the correct technology depends on your application requirements!

We pride ourselves on being experts in both ultrasonic and radar technology, and have a wide range of sensors and options to suit your needs. All of our sensors come with intrinsically safe options, so you can be sure that the sensors you choose can be safely installed in hazardous locations. We offer worldwide support, both remotely and on-site, so whatever your question, please do not hesitate to give one of our friendly service teams a call.

Below you'll find a breakdown of both technologies to help better your understanding and ultimately, giving you the knowledge you need to make the best choice for your application!

Pulsar Measurement - We're experts in both

We know that there are other manufacturers out there that will tell you different things about Ultrasonic and Radar technology. No doubt you've heard things like "Radar is the better Ultrasonic" and "Radar is the future", well we're here to bust those myths because it's just not true! At Pulsar Measurement we believe both technologies have their place in the market and choosing the correct technology depends on your application requirements!

We pride ourselves on being experts in both ultrasonic and radar technology, and have a wide range of sensors and options to suit your needs. All of our sensors come with intrinsically safe options, so you can be sure that the sensors you choose can be safely installed in hazardous locations. We offer worldwide support, both remotely and on-site, so whatever your question, please do not hesitate to give one of our friendly service teams a call.

Below you'll find a breakdown of both technologies to help better your understanding and ultimately, giving you the knowledge you need to make the best choice for your application!

What Radar do Pulsar Measurement offer?

PULSAR REFLECT™ is our latest 2-wire radar level sensor, providing accurate level or volume monitoring of liquids and solids in critical measurement applications, and ensuring complete peace of mind with a product that requires minimal skills and human intervention, thereby minimising the lifetime cost of ownership. PULSAR REFLECT™ also outperforms existing products that, up until now, required frequent and costly manual intervention to validate measurement integrity.

Radar summary

- Great for applications with rapid temperature fluctuations.

- Ideal for when the dielectric constant of the material is high.

- Preferred for applications with gas and vapor present.

RADAR

So how does Radar technology work?

There are a few different types of radar technology, but the type of radar technology we use at Pulsar Measurement is FMCW (Frequency Modulated Continuous Wave) Radar. It differs from pulsed radar in that an electromagnetic signal is continuously transmitted. The frequency of this signal changes over time, generally in a sweep across a set bandwidth. The difference in frequency between the transmitted and received (reflected) signal is determined by mixing the two signals, producing a new signal that can be measured to determine distance or volume.

When should Radar be considered?

Thanks to our industry leading technology, and built-in DATEM software, you can usually count on ultrasonic level sensors to get the job done for you. However, there are some instances where you want to consider using a radar sensor including applications with rapid temperature changes or when Gas and Vapour are present. We've gone through these in a little more detail below!

RADAR

So how does Radar technology work?

There are a few different types of radar technology, but the type of radar technology we use at Pulsar Measurement is FMCW (Frequency Modulated Continuous Wave) Radar. It differs from pulsed radar in that an electromagnetic signal is continuously transmitted. The frequency of this signal changes over time, generally in a sweep across a set bandwidth. The difference in frequency between the transmitted and received (reflected) signal is determined by mixing the two signals, producing a new signal that can be measured to determine distance or volume.

When should Radar be considered?

Thanks to our industry leading technology, and built-in DATEM software, you can usually count on ultrasonic level sensors to get the job done for you. However, there are some instances where you want to consider using a radar sensor including applications with rapid temperature changes or when Gas and Vapour are present. We've gone through these in a little more detail below!

What Radar do you offer?

REFLECT™ is our latest 2-wire radar level sensor, providing accurate level or volume monitoring of liquids and solids in critical measurement applications, and ensuring complete peace of mind with a product that requires minimal skills and human intervention, thereby minimizing the lifetime cost of ownership. REFLECT™ also outperforms exsisting products that, up until now, required frequent and costly manual intervention to validate measurement integrity.

Radar summary

- Great for applications with rapid temperature fluctuations.

- Ideal for when the dielectric constant of the material is high.

- Preferred for applications with gas and vapor present.

RADAR

So how does Radar technology work?

There are a few different types of radar technology, but the type of radar technology we use at Pulsar Measurement is FMCW (Frequency Modulated Continuous Wave) Radar. It differs from pulsed radar in that an electromagnetic signal is continuously transmitted. The frequency of this signal changes over time, generally in a sweep across a set bandwidth. The difference in frequency between the transmitted and received (reflected) signal is determined by mixing the two signals, producing a new signal that can be measured to determine distance or volume.

When should Radar be considered?

Thanks to our industry leading technology, and built-in DATEM software, you can usually count on ultrasonic level sensors to get the job done for you. However, there are some instances where you want to consider using a radar sensor including applications with rapid temperature changes or when Gas and Vapour are present. We've gone through these in a little more detail below!

What Radar do you offer?

REFLECT™ is our latest 2-wire radar level sensor, providing accurate level or volume monitoring of liquids and solids in critical measurement applications, and ensuring complete peace of mind with a product that requires minimal skills and human intervention, thereby minimizing the lifetime cost of ownership. REFLECT™ also outperforms exsisting products that, up until now, required frequent and costly manual intervention to validate measurement integrity.

Radar summary

- Great for applications with rapid temperature fluctuations.

- Ideal for when the dielectric constant of the material is high.

- Preferred for applications with gas and vapor present.

RADAR

So how does Radar technology work?

There are a few different types of radar technology, but the type of radar technology we use at Pulsar Measurement is FMCW (Frequency Modulated Continuous Wave) Radar. It differs from pulsed radar in that an electromagnetic signal is continuously transmitted. The frequency of this signal changes over time, generally in a sweep across a set bandwidth. The difference in frequency between the transmitted and received (reflected) signal is determined by mixing the two signals, producing a new signal that can be measured to determine distance or volume.

When should Radar be considered?

Thanks to our industry leading technology, and built-in DATEM software, you can usually count on ultrasonic level sensors to get the job done for you. However, there are some instances where you want to consider using a radar sensor including applications with rapid temperature changes or when Gas and Vapour are present. We've gone through these in a little more detail below!

What Radar do you offer?

REFLECT™ is our latest 2-wire radar level sensor, providing accurate level or volume monitoring of liquids and solids in critical measurement applications, and ensuring complete peace of mind with a product that requires minimal skills and human intervention, thereby minimizing the lifetime cost of ownership. REFLECT™ also outperforms exsisting products that, up until now, required frequent and costly manual intervention to validate measurement integrity.

Radar summary

- Great for applications with rapid temperature fluctuations.

- Ideal for when the dielectric constant of the material is high.

- Preferred for applications with gas and vapor present.

RADAR

So how does Radar technology work?

There are a few different types of radar technology, but the type of radar technology we use at Pulsar Measurement is FMCW (Frequency Modulated Continuous Wave) Radar. It differs from pulsed radar in that an electromagnetic signal is continuously transmitted. The frequency of this signal changes over time, generally in a sweep across a set bandwidth. The difference in frequency between the transmitted and received (reflected) signal is determined by mixing the two signals, producing a new signal that can be measured to determine distance or volume.

When should Radar be considered?

Thanks to our industry leading technology, and built-in DATEM software, you can usually count on ultrasonic level sensors to get the job done for you. However, there are some instances where you want to consider using a radar sensor including applications with rapid temperature changes or when Gas and Vapour are present. We've gone through these in a little more detail below!

What Radar do you offer?

REFLECT™ is our latest 2-wire radar level sensor, providing accurate level or volume monitoring of liquids and solids in critical measurement applications, and ensuring complete peace of mind with a product that requires minimal skills and human intervention, thereby minimizing the lifetime cost of ownership. REFLECT™ also outperforms exsisting products that, up until now, required frequent and costly manual intervention to validate measurement integrity.

Radar summary

- Great for applications with rapid temperature fluctuations.

- Ideal for when the dielectric constant of the material is high.

- Preferred for applications with gas and vapor present.

Temperature Fluctuations

With applications that are likely to exhibit steep temperature changes, this could affect the quality of the measurement when ultrasonic is used . As temperature increases, the sound waves travel faster to and from the target, while the target may not have shifted, it will seem to the sensor that the target is closer due to the increase in the speed of the waves. Our ultrasonic technology compensates for these temperature changes with a built-in temperature sensor so im most cases you can use either Ultrasonic or Radar, however, if the process temperature rapidly changes it can cause a lag in the measurement readings. Therefore, if absolute accuracy is important for the measurement, you should strongly consider radar technology for this type of application.

Gas and Vapour

The speed of sound will change if the composition of gas above the measurement level changes. Ultrasonic transducers usually cannot ordinarily compensate for this. If the gas is not air, you can set the speed of sound to a different value to compensate, but this is only helpful if the gas composition remains at a constant. In these situations, the application would be more suited to a radar sensor. Our PULSAR REFLECT™ 2-wire radar level sensor is well equiped for this type of application and with minimal skill requirement and human intervention could be the solution you're looking for!

Temperature Fluctuations

With applications that are likely to exhibit steep temperature changes, this could affect the quality of the measurement when ultrasonic is used . As temperature increases, the sound waves travel faster to and from the target, while the target may not have shifted, it will seem to the sensor that the target is closer due to the increase in the speed of the waves. Our ultrasonic technology compensates for these temperature changes with a built-in temperature sensor so im most cases you can use either Ultrasonic or Radar, however, if the process temperature rapidly changes it can cause a lag in the measurement readings. Therefore, if absolute accuracy is important for the measurement, you should strongly consider radar technology for this type of application.

Gas and Vapour

The speed of sound will change if the composition of gas above the measurement level changes. Ultrasonic transducers usually cannot ordinarily compensate for this. If the gas is not air, you can set the speed of sound to a different value to compensate, but this is only helpful if the gas composition remains at a constant. In these situations, the application would be more suited to a radar sensor. Our REFLECT™ 2-wire radar level sensor is well equiped for this type of application and with minimal skill requirement and human intervention could be the solution you're looking for!

Temperature fluctuations

With applications that are likely to exhibit steep temperature changes, this could affect the quality of the measurement when ultrasonic is used . As temperature increases, the sound waves travel faster to and from the target, while the target may not have shifted, it will seem to the sensor that the target is closer due to the increase in the speed of the waves. Our ultrasonic technology compensates for these temperature changes with a built-in temperature sensor so im most cases you can use either Ultrasonic or Radar, however, if the process temperature rapidly changes it can cause a lag in the measurement readings. Therefore, if absolute accuracy is important for the measurement, you should strongly consider radar technology for this type of application.

Gas and Vapour

The speed of sound will change if the composition of gas above the measurement level changes. Ultrasonic transducers usually cannot ordinarily compensate for this. If the gas is not air, you can set the speed of sound to a different value to compensate, but this is only helpful if the gas composition remains at a constant. In these situations, the application would be more suited to a radar sensor. Our REFLECT™ 2-wire radar level sensor is well equiped for this type of application and with minimal skill requirement and human intervention could be the solution you're looking for!

Temperature fluctuations

With applications that are likely to exhibit steep temperature changes, this could affect the quality of the measurement when ultrasonic is used . As temperature increases, the sound waves travel faster to and from the target, while the target may not have shifted, it will seem to the sensor that the target is closer due to the increase in the speed of the waves. Our ultrasonic technology compensates for these temperature changes with a built-in temperature sensor so im most cases you can use either Ultrasonic or Radar, however, if the process temperature rapidly changes it can cause a lag in the measurement readings. Therefore, if absolute accuracy is important for the measurement, you should strongly consider radar technology for this type of application.

Gas and Vapour

The speed of sound will change if the composition of gas above the measurement level changes. Ultrasonic transducers usually cannot ordinarily compensate for this. If the gas is not air, you can set the speed of sound to a different value to compensate, but this is only helpful if the gas composition remains at a constant. In these situations, the application would be more suited to a radar sensor. Our REFLECT™ 2-wire radar level sensor is well equiped for this type of application and with minimal skill requirement and human intervention could be the solution you're looking for!

Temperature

Fluctuations

With applications that are likely to exhibit steep temperature changes, this could affect the quality of the measurement when ultrasonic is used . As temperature increases, the sound waves travel faster to and from the target, while the target may not have shifted, it will seem to the sensor that the target is closer due to the increase in the speed of the waves. Our ultrasonic technology compensates for these temperature changes with a built-in temperature sensor so im most cases you can use either Ultrasonic or Radar, however, if the process temperature rapidly changes it can cause a lag in the measurement readings. Therefore, if absolute accuracy is important for the measurement, you should strongly consider radar technology for this type of application.

Gas and Vapour

The speed of sound will change if the composition of gas above the measurement level changes. Ultrasonic transducers usually cannot ordinarily compensate for this. If the gas is not air, you can set the speed of sound to a different value to compensate, but this is only helpful if the gas composition remains at a constant. In these situations, the application would be more suited to a radar sensor. Our REFLECT™ 2-wire radar level sensor is well equiped for this type of application and with minimal skill requirement and human intervention could be the solution you're looking for!

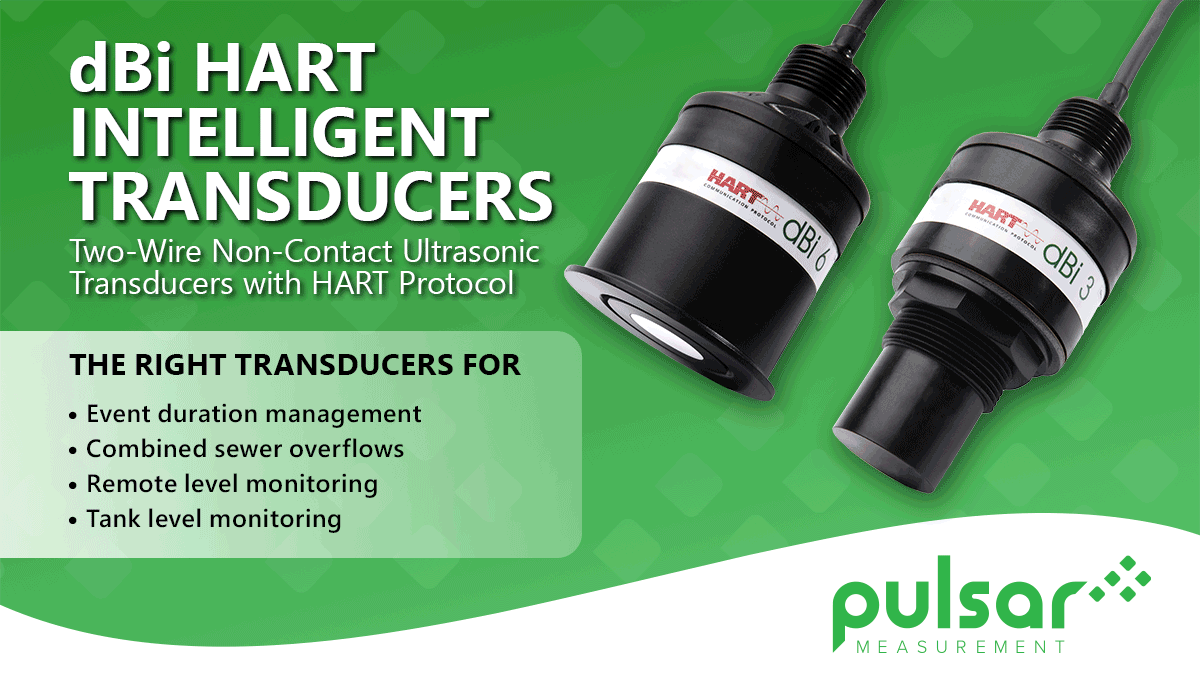

ULTRASONIC

So how does ultrasonic technology work?

Ultrasonic level sensors measure using the same principle used by bats to navigate Emitting a short pulse of high frequency sound and measuring the time taken for an echo to return. Ultrasonic sensors have an onboard circuit that creates a high amplitude pulse at the required frequency to excite a piezo electric crystal. The excited crystal will then emit a pulse of sound from the face of the sensor and is then re-excited by those returning echoes.

Is Ultrasonic technology out of date?

Absolutely not. Ultrasonic level sensors have been the bread and butter of any applications measurement needs for a long time now, and that's not set to change anytime soon; no matter what some providers will tell you. However, advancements in Radar technology do mean that for certain applications they are more effective and so would be preferred.

When should Ultrasonic be used?

Ultrasonic technology is effective in most situations with a few exceptions. Chances are you'll be able to use our Ultrasonic instrumentation in your application in some capacity, and if it's really not applicable our experienced staff will be there to advise! Pulsar Measurement offer both technologies as a solution and will recommend the correct one based on your specific application and measurement requirements. The choice is yours!

Ultrasonic Summary

- Great for when the dielectric constant of the material is low.

- Ideal for applications with a lot of obstructions due to a tighter beam angle and Pulsar Measurement’s built-in DATEM software.

- A great all-round, established and proven technology that with the inclusion of DATEM software will handle most applications with ease.

ULTRASONIC

So how does ultrasonic technology work?

Ultrasonic level sensors measure using the same principle used by bats to navigate Emitting a short pulse of high frequency sound and measuring the time taken for an echo to return. Ultrasonic sensors have an onboard circuit that creates a high amplitude pulse at the required frequency to excite a piezo electric crystal. The excited crystal will then emit a pulse of sound from the face of the sensor and is then re-excited by those returning echoes.

Is Ultrasonic technology out of date?

Absolutely not. Ultrasonic level sensors have been the bread and butter of any applications measurement needs for a long time now, and that's not set to change anytime soon; no matter what some providers will tell you. However, advancements in Radar technology do mean that for certain applications they are more effective and so would be preferred.

When should Ultrasonic be used?

Ultrasonic technology is effective in most situations with a few exceptions. Chances are you'll be able to use our Ultrasonic instrumentation in your application in some capacity, and if it's really not applicable our experienced staff will be there to advise! Pulsar Measurement offer both technologies as a solution and will recommend the correct one based on your specific application and measurement requirements. The choice is yours!

Ultrasonic Summary

- Great for when the dielectric constant of the material is low.

- Ideal for applications with a lot of obstructions due to a tighter beam angle and Pulsar Measurement’s built-in DATEM software.

- A great all-round, established and proven technology that with the inclusion of DATEM software will handle most applications with ease.

ULTRASONIC

So how does ultrasonic technology work?

Ultrasonic level sensors measure using the same principle used by bats to navigate Emitting a short pulse of high frequency sound and measuring the time taken for an echo to return. Ultrasonic sensors have an onboard circuit that creates a high amplitude pulse at the required frequency to excite a piezo electric crystal. The excited crystal will then emit a pulse of sound from the face of the sensor and is then re-excited by those returning echoes.

Is Ultrasonic technology out of date?

Absolutely not. Ultrasonic level sensors have been the bread and butter of any applications measurment needs for a long time now, and that's not set to change anytime soon; no matter what some providers will tell you. However, advancements in Radar technology do mean that for certain applications they are more effective and so would be preferred.

When should Ultrasonic be used?

Ultrasonic technology is effective in most situations with a few exceptions. Chances are you'll be able to use our Ultrasonic instrumentation in your application in some capacity, and if it's really not applicable our experienced staff will be there to advise! Pulsar Measurement offer both technologies as a solution and will recommend the correct one based on your specific application and measurement requirements. The choice is yours!

Ultrasonic Summary

- Great for when the dielectric constant of the material is low.

- Ideal for applications with a lot of obstructions due to a tighter beam angle and Pulsar Measurement’s built-in DATEM software.

- A great all-round, established and proven technology that with the inclusion of DATEM software will handle most applications with ease.

ULTRASONIC

So how does ultrasonic technology work?

Ultrasonic level sensors measure using the same principle used by bats to navigate Emitting a short pulse of high frequency sound and measuring the time taken for an echo to return. Ultrasonic sensors have an onboard circuit that creates a high amplitude pulse at the required frequency to excite a piezo electric crystal. The excited crystal will then emit a pulse of sound from the face of the sensor and is then re-excited by those returning echoes.

Is Ultrasonic technology out of date?

Absolutely not. Ultrasonic level sensors have been the bread and butter of any applications measurment needs for a long time now, and that's not set to change anytime soon; no matter what some providers will tell you. However, advancements in Radar technology do mean that for certain applications they are more effective and so would be preferred.

When should Ultrasonic be used?

Ultrasonic technology is effective in most situations with a few exceptions. Chances are you'll be able to use our Ultrasonic instrumentation in your application in some capacity, and if it's really not applicable our experienced staff will be there to advise! Pulsar Measurement offer both technologies as a solution and will recommend the correct one based on your specific application and measurement requirements. The choice is yours!

Ultrasonic Summary

- Great for when the dielectric constant of the material is low.

- Ideal for applications with a lot of obstructions due to a tighter beam angle and Pulsar Measurement’s built-in DATEM software.

- A great all-round, established and proven technology that with the inclusion of DATEM software will handle most applications with ease.

ULTRASONIC

So how does ultrasonic technology work?

Ultrasonic level sensors measure using the same principle used by bats to navigate Emitting a short pulse of high frequency sound and measuring the time taken for an echo to return. Ultrasonic sensors have an onboard circuit that creates a high amplitude pulse at the required frequency to excite a piezo electric crystal. The excited crystal will then emit a pulse of sound from the face of the sensor and is then re-excited by those returning echoes.

Is Ultrasonic technology out of date?

Absolutely not. Ultrasonic level sensors have been the bread and butter of any applications measurment needs for a long time now, and that's not set to change anytime soon; no matter what some providers will tell you. However, advancements in Radar technology do mean that for certain applications they are more effective and so would be preferred.

When should Ultrasonic be used?

Ultrasonic technology is effective in most situations with a few exceptions. Chances are you'll be able to use our Ultrasonic instrumentation in your application in some capacity, and if it's really not applicable our experienced staff will be there to advise! Pulsar Measurement offer both technologies as a solution and will recommend the correct one based on your specific application and measurement requirements. The choice is yours!

Ultrasonic Summary

- Great for when the dielectric constant of the material is low.

- Ideal for applications with a lot of obstructions due to a tighter beam angle and Pulsar Measurement’s built-in DATEM software.

- A great all-round, established and proven technology that with the inclusion of DATEM software will handle most applications with ease.

Dielectric Constant

What is Dielectric Constant?

Dielectric constant is a property which represents the ability of a substance to store electrical energy in an electric field. It is an expression of the extent to which a material holds or concentrates electric flux.

Dielectric Constant and Radar Measurement

Radar technology works by sending out an electromagnetic signal towards the liquid via the sensor. The signal then hits the liquid surface and returns toward the sensor. Since a higher dielectric means a higher electric flux density, the higher the dielectric constant the easier it is for the radar signal to reflect off the media, rather than travel through it. Generally, for substances with a higher dielectric constant, radar would be the most suitable technology. A material with a low dielectric constant does not provide a significant enough boundary for the radar signal to reflect off of and return back to the sensor.

Dielectric Constant and Ultrasonic Measurement

Ultrasonic measurement is unaffected by dielectric constant because it does not work on the basis of electromagnetism. Where as Radar level sensors are dependent on the dielectric constant of the medium.

How do i find out my Dielectric Constant rating?

If you’re not sure of your material’s dielectric constant, don’t worry, we have a dielectric constant guide where you can see the value for the majority of materials, and our knowledgeable sales and support team will be able to help you decide which technology is best for that particular application.

Dielectric Constant

What is Dielectric Constant?

Dielectric constant is a property which represents the ability of a substance to store electrical energy in an electric field. It is an expression of the extent to which a material holds or concentrates electric flux.

Dielectric Constant and Radar Measurement

Radar technology works by sending out an electromagnetic signal towards the liquid via the sensor. The signal then hits the liquid surface and returns toward the sensor. Since a higher dielectric means a higher electric flux density, the higher the dielectric constant the easier it is for the radar signal to reflect off the media, rather than travel through it. Generally, for substances with a higher dielectric constant, radar would be the most suitable technology. A material with a low dielectric constant does not provide a significant enough boundary for the radar signal to reflect off of and return back to the sensor.

Dielectric Constant and Ultrasonic Measurement

Ultrasonic measurement is unaffected by dielectric constant because it does not work on the basis of electromagnetism. Where as Radar level sensors are dependent on the dielectric constant of the medium.

How do i find out my Dielectric Constant rating?

If you’re not sure of your material’s dielectric constant, don’t worry, we have a dielectric constant guide where you can see the value for the majority of materials, and our knowledgeable sales and support team will be able to help you decide which technology is best for that particular application.

Dielectric Constant

What is Dielectric Constant?

Dielectric constant is a property which represents the ability of a substance to store electrical energy in an electric field. It is an expression of the extent to which a material holds or concentrates electric flux.

Dielectric Constant and Radar Measurement

Radar technology works by sending out an electromagnetic signal towards the liquid via the sensor. The signal then hits the liquid surface and returns toward the sensor. Since a higher dielectric means a higher electric flux density, the higher the dielectric constant the easier it is for the radar signal to reflect off the media, rather than travel through it. Generally, for substances with a higher dielectric constant, radar would be the most suitable technology. A material with a low dielectric constant does not provide a significant enough boundary for the radar signal to reflect off of and return back to the sensor.

Dielectric Constant and Ultrasonic Measurement

Ultrasonic measurement is unaffected by dielectric constant because it does not work on the basis of electromagnetism. Where as Radar level sensors are dependent on the dielectric constant of the medium.

How do i find out my Dielectric Constant rating?

If you’re not sure of your material’s dielectric constant, don’t worry, we have a dielectric constant guide where you can see the value for the majority of materials, and our knowledgeable sales and support team will be able to help you decide which technology is best for that particular application.

Dielectric Constant

What is Dielectric Constant?

Dielectric constant is a property which represents the ability of a substance to store electrical energy in an electric field. It is an expression of the extent to which a material holds or concentrates electric flux.

Dielectric Constant and Radar Measurement

Radar technology works by sending out an electromagnetic signal towards the liquid via the sensor. The signal then hits the liquid surface and returns toward the sensor. Since a higher dielectric means a higher electric flux density, the higher the dielectric constant the easier it is for the radar signal to reflect off the media, rather than travel through it. Generally, for substances with a higher dielectric constant, radar would be the most suitable technology. A material with a low dielectric constant does not provide a significant enough boundary for the radar signal to reflect off of and return back to the sensor.

Dielectric Constant and Ultrasonic Measurement

Ultrasonic measurement is unaffected by dielectric constant because it does not work on the basis of electromagnetism. Where as Radar level sensors are dependent on the dielectric constant of the medium.

How do i find out my Dielectric Constant rating?

If you’re not sure of your material’s dielectric constant, don’t worry, we have a dielectric constant guide where you can see the value for the majority of materials, and our knowledgeable sales and support team will be able to help you decide which technology is best for that particular application.

Dielectric Constant

What is Dielectric Constant?

Dielectric constant is a property which represents the ability of a substance to store electrical energy in an electric field. It is an expression of the extent to which a material holds or concentrates electric flux.

Dielectric Constant and Radar Measurement

Radar technology works by sending out an electromagnetic signal towards the liquid via the sensor. The signal then hits the liquid surface and returns toward the sensor. Since a higher dielectric means a higher electric flux density, the higher the dielectric constant the easier it is for the radar signal to reflect off the media, rather than travel through it. Generally, for substances with a higher dielectric constant, radar would be the most suitable technology. A material with a low dielectric constant does not provide a significant enough boundary for the radar signal to reflect off of and return back to the sensor.

Dielectric Constant and Ultrasonic Measurement

Ultrasonic measurement is unaffected by dielectric constant because it does not work on the basis of electromagnetism. Where as Radar level sensors are dependent on the dielectric constant of the medium.

How do i find out my Dielectric Constant rating?

If you’re not sure of your material’s dielectric constant, don’t worry, we have a dielectric constant guide where you can see the value for the majority of materials, and our knowledgeable sales and support team will be able to help you decide which technology is best for that particular application.