Chemical level and flow monitoring

Liquid level and flow monitoring in the chemical industry

What is Liquid level and flow monitoring?

Liquid level and flow monitoring is crucial to the smooth operation of a chemical plant, it ensures that processes are working effectively and to their maximum capacity, as well as help to keep tight control over stock levels. A range of control units and ultrasonic and radar level sensors can provide accurate tank level monitoring, all with chemically resistant options, and is suitable for use on a wide variety of substances.

What about closed pipe monitoring?

For closed pipe monitoring, our transit time sensors simply strap to the outside of pipes, enabling a quick and easy installation without having to cause downtime to the operation. This gives plant operators full visibility of their processes and operations.

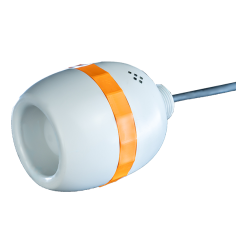

Our TTFM 6.1 product gives a static option, which once installed gives consistent and accurate readings. Whereas the new PTFM 6.1 offers operators portability and the ability for the unit to be used on multiple pipes once installed, it’s easy to set up and built to last so it can be moved between pipes easily.

How can Pulsar Measurement help?

Pulsar Measurement has a range of solutions that not only deliver accurate and reliable measurement readings but also have the added benefit of being non-contacting, which helps eliminate any risk to the operator.

Please select from a range of suggested Pulsar Measurement products below:

Product Configurator

The Pulsar Measurement product configurator allows you to select the applications specific to you and discover the most appropriate solutions for your requirements.