Tank Level Measurement in Water & Wastewater

Tank Level Monitoring

What is Tank Level Monitoring?

Tank level monitoring is the monitoring of the level within the tank that allows operators to monitor, program alarms, and report tank level, interface level, and tank volumes for production and accounting.

How is Tank Level Monitoring beneficial?

Non-contacting tank level monitoring can offer some serious advantages, especially when looking at Ferric dosing tanks, for many health and safety reasons. This means staff doesn't have to put themselves at risk by climbing to the top of a tank for an indication of level. Additionally, tank level monitoring allows for easy and more efficient stock control, and automated pumping routines with Pulsar Measurement controllers allow the entire process to become more streamlined.

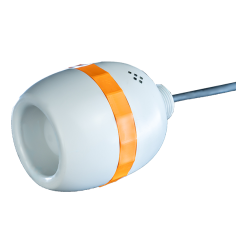

Pulsar has a range of technologies that are suitable for this application. Using Pulsar radar technology, it is possible to view the level from outside a plastic tank, preventing spillage and giving accurate indications for re-filling and stock levels. Ultrasonic works in the same way, however, the transducer face is usually mounted inside the tank and can zone in on the true level, ignoring all other competing echoes.

Pulsar Measurement controllers come with a range of pre-programmed tank shapes and the ability to program custom tank shapes, with a range of level sensors from 0 – 40 m (0 – 131.2 ft) there is sure to be a level measurement solution that meets your application needs.

Please view a range of suggested Pulsar Measurement products below:

Product Configurator

The Pulsar Measurement product configurator allows you to select the applications specific to you and discover the most appropriate solutions for your requirements.