Solids Flow Meters and Level Sensors for the Pulp & Paper industry

Solids Level and Flow Monitoring

What are the benefits of choosing this setup?

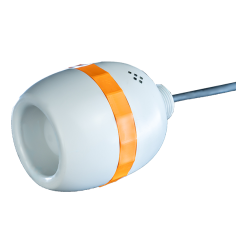

Foam face ultrasonic or radar sensors help protect the sensor from harsh environments and allows for accurate and reliable solid level measurement. The non-contacting nature of the sensors eliminates the need for maintenance as well as the worry of wear and tear on the product, when compared with other contacting level sensors. Another benefit is that the downtime needed for installation is non-existent as the sensor doesn't come into contact with the measuring substance.

Why choose Pulsar Measurement products?

Pulsar Measurement can provide state-of-the-art acoustic technology which will help to monitor flow in closed pipes. Our non-contacting products can be simply strapped to the outside of a pipe which not only means that downtime for installation is non-existent but also helps to aid plant operators with clogged or blocked chute detection. Additionally, level sensors from Pulsar Measurement are completely non-contacting, meaning they are mounted above the measurement surface, removing costly installations and maintenance costs.

Please see a range of suggested products below:

Product Configurator

The Pulsar Measurement product configurator allows you to select the applications specific to you and discover the most appropriate solutions for your requirements.