Flow meters and Level Measurement for Solids

Solids flow and level measurement in the pharmaceutical industry

Why is solid flow measurement important for the pharmaceutical industry?

Measuring the flow of solids through pipes as they transfer product from one area of the pharmaceutical plant to the other helps to detect blockages, foreign objects, a burst pipe, high flow, low flow, or no-flow conditions. The solids flow measurement range from Pulsar Measurement is non-contacting and straps to the outside of a pipe. This means there are no downtime costs for installation, and it doesn't come into contact with the measurement substance, therefore maintaining the integrity of the product.

What about level measurement?

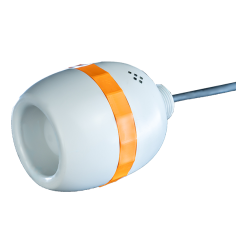

Foam face ultrasonic or radar sensors can help get the accurate solid level measurement you are looking for. Non-contacting sensors require low to no maintenance and eliminate the fear of wear and tear. In addition, the downtime needed for installation is non-existent as the sensor doesn't come into contact with the measuring substance. Radar sensors can read through the top of PVC plastic tanks for accurate level measurement without breaking into the tank.

How can Pulsar Measurement help?

Pulsar Measurement has a range of solutions available which provide accurate and reliable measurement readings.

You can view a range of suggested Pulsar Measurement products below:

Product Configurator

The Pulsar Measurement product configurator allows you to select the applications specific to you and discover the most appropriate solutions for your requirements.