PCB Manufacturing

Pulsar Measurement is a leading UK based contract electronics manufacturer who can take your design from concept to reality.

Our manufacturing team deliver trusted, high-quality electronic manufacturing services from our advanced UK based facility in Essex to customers around the globe. With over 27 years of experience, we provide complete solutions, from PCB assembly to full product build, backed by ISO 9001, ISO14001, ATEX, and UL certifications. Precision, reliability, and collaboration are at the heart of everything we do

Automated Optical Inspection (AOI)

What is AOI?

Automated Optical Inspection (AOI) is a technique used to ensure the flawless execution of PCB assemblies with unprecedented accuracy. Leveraging advanced optical technologies and sophisticated algorithms, AOI is designed to scrutinize the components on the surface of PCB assemblies with meticulous attention to detail.

Click here to view More Details

What is AOI?

Automated Optical Inspection (AOI) is a technique used to ensure the flawless execution of PCB assemblies with unprecedented accuracy. Leveraging advanced optical technologies and sophisticated algorithms, AOI is designed to scrutinize the components on the surface of PCB assemblies with meticulous attention to detail.

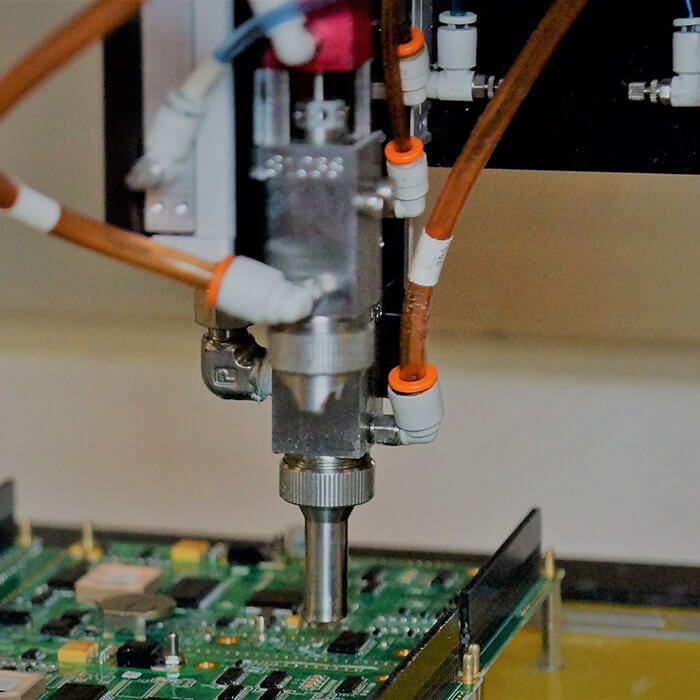

How does AOI work?

At the heart of AOI lies a complex system of high-resolution cameras and advanced optics. These

cameras capture detailed images of the PCB assembly's surface, creating a visual representation

that

serves as the basis for thorough inspection. As the PCB assembly moves through the AOI machine,

the

cameras capture multiple images from different angles and lighting conditions, this

multi-perspective approach enhances the system's ability to detect a wide range of defects with

precision.

The acquired images undergo sophisticated pre-processing algorithms to enhance clarity

and remove any artifacts that might interefere with the inspection process. This step ensures

that

the inspection is based on clean and accurate data. AOI relies on reference data, typically

generated from the original design files (Gerber files) or a golden sample, to establish the

expected appearance of a defect-free PCB assembly. The captured images are then compared to this

reference data to identify any deviations or anomalies.

Advanced defect recognition algorithms

analyze the images pixel by pixel, identifying variations, irregularities, and defects in the

PCB

assembly. These algorithms are designed to recognize various types of defects, including solder

joint issues, component misplacements, polarity errors, and more.

Detected defects are classified

based on their severity and relevance to the functionality of the PCB assembly. The AOI system

generates detailed reports that highlight the location, type and size of defects, enabling quick

and

informed decision-making for quality control teams. In essence, AOI is a combination of

cutting-edge

optics, sophisticated algorithms, and intelligent machine learning, all working seamlessly to

scrutinize the surface of PCB assemblies with unparalleled precision. As technology advances,

AOI

continues to evolve, setting new standards for quality control in electronic manufacturing and

ensuring that every PCB that rolls off the assembly line meets the highest levels of reliability

and

performance.

To find out more about our AOI processes, contact our friendly team today.

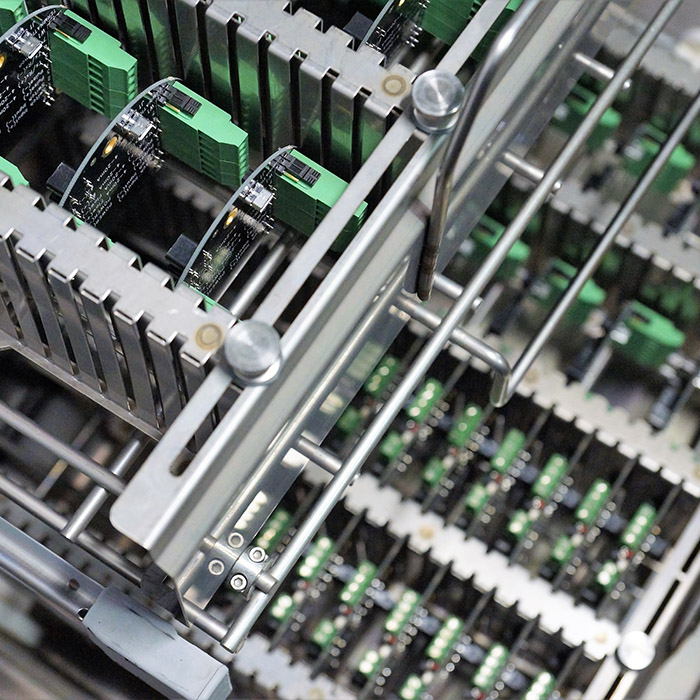

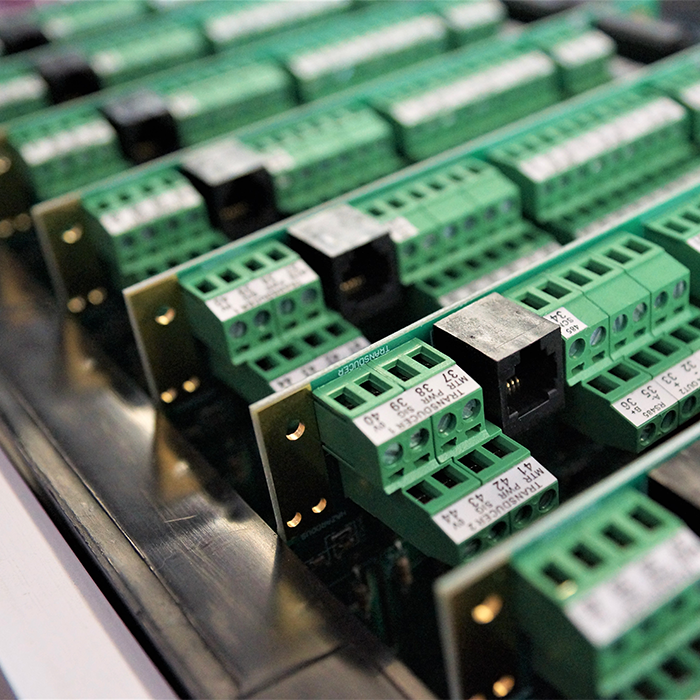

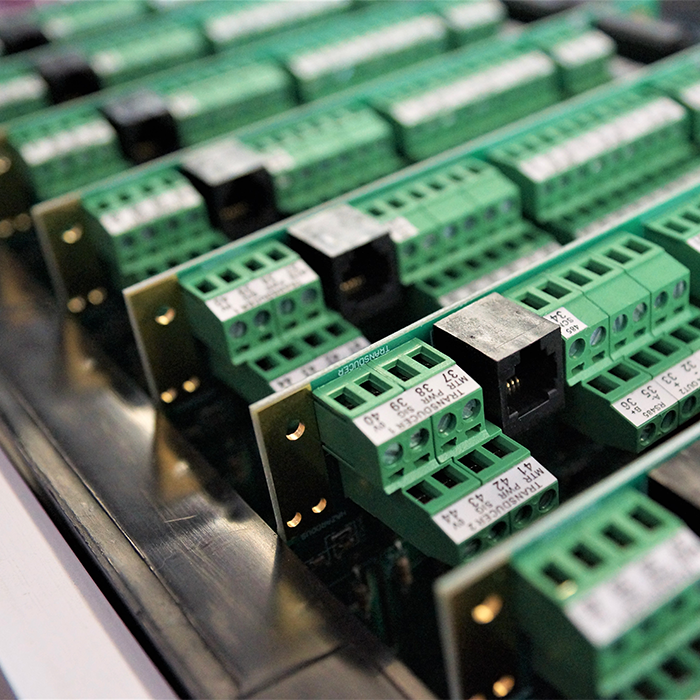

Box Build Assembly

What is Box Build?

Box Build, also known as System Integration or Turnkey Assembly, is the final and crucial phase in PCB manufacturing where the assembled PCB is integrated into a complete electronic system or device. This all-encompassing process involves the assembly of various components such as PCBs, cables, connectors, and mechanical enclosures, resulting in a fully functional and ready-to-use electronic product.

Click here to view More Details

What is Box Build?

Box Build, also known as System Integration or Turnkey Assembly, is the final and crucial phase in PCB manufacturing where the assembled PCB is integrated into a complete electronic system or device. This all-encompassing process involves the assembly of various components such as PCBs, cables, connectors, and mechanical enclosures, resulting in a fully functional and ready-to-use electronic product.

What does our Box Build service include?

As part of Pulsar Manufacturing's service for the complete build of electronic products, we provide box-build assembly for sub-systems and modules as well as for full product integration into an outer case or metal or plastic case or enclosure. Working with several sheet metal and plastic moulding companies, Pulsar Manufacturing can assist with advising and building the complete unit assembly as well as 3D printing prototypes before tooling costs are incurred in the final design build.

Advantages of Box Build

Simplified Supply Chain: Box Build assembly streamlines the supply chain by consolidating various components and assembly processes under a single provider, reducing complexity and lead times.

Cost Efficiency: By entrusting the complete assembly to a single partner, you benefit from cost savings associated with streamlined logistics, reduced handling, and efficient coordination.

Time Savings: Box Build eliminates the need for multiple suppliers and the associated coordination efforts, resulting in faster production cycles and quicker time-to-market for your electronic products.

Quality Control: With integrated testing and quality assurance processes, Box Build ensures that every electronic system leaving our facility meets or exceeds industry.

Why choose Pulsar Manufacturing?

Pulsar Manufacturing takes pride in being able to offer our customers full support from the very beginning of the design process, right through to the final build stages and prototype production. Our communication channels with our clients are always open and transparent so full control over the product and its quality is achievable. We are also ISO9001, ATEX, and UL certified which ensures our products are built to the best standards possible.

Contact our friendly team to find out more.

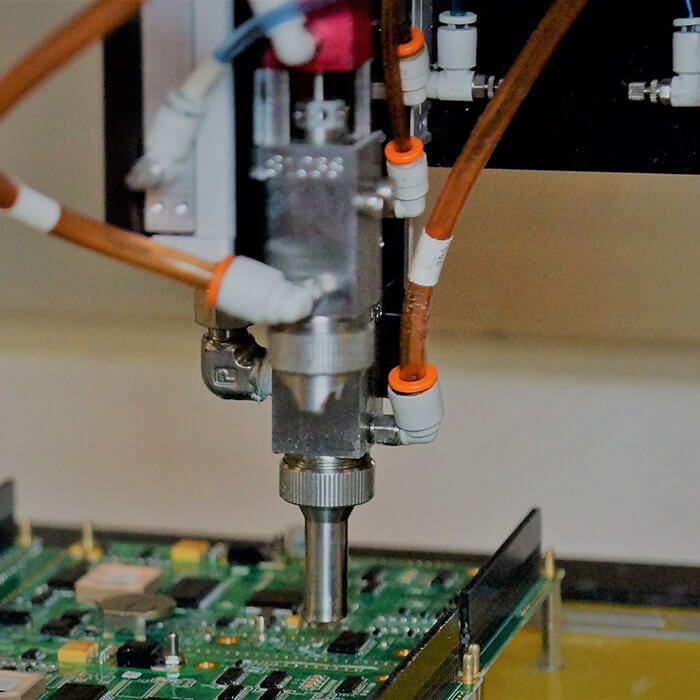

Conformal Coating

What is Conformal Coating?

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards. Conformal coating is typically applied at 20-25μm thickness, and designed to protect against moisture and other harsher conditions. Conformal Coating is now considered standard practice in PCB assembly and is applicable across a wide array of different industries.

Click here to view More Details

What is Conformal Coating?

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards. Conformal coating is typically applied at 20-25μm thickness, and designed to protect against moisture and other harsher conditions. Conformal Coating is now considered standard practice in PCB assembly and is applicable across a wide array of different industries...

How is Conformal Coating applied?

There are several different ways that you can apply conformal coatings, including dip coating, brushing, spraying, and dispensing. A variety of different materials can be used, such as perylene, silicones, urethanes, and acrylics. Each method and material has it's own characteristics for different purposes. The conformal coatings contain a fluorescent dye which although is unclear to the naked eye, becomes visible under Ultraviolet lighting. This not only helps our specially trained technicians apply as per the engineering drawings but also helps to aid in coating coverage inspection..

What are the advantages of Conformal Coating?

Conformal Coatings can prevent problems with printed circuit boards such as the ingress of dirt, moisture, dust, can help to protect your PCB against rust, abrasion, chemical damage, mechanical stress, and vibration. All of this helps to extend the life of your product, and reduce failure rates.

Why choose Pulsar Manufacturing?

Customer satisfaction and product quality are at the heart of everything we do at Pulsar Measurement. With over 25 years of experience in PCB Manufacturing, we are well-equipped to produce highly reliable electronic assemblies. We take pride in being ATEX, UL, and ISO9001 certified which holds us accountable to the highest possible standards.

For a site tour, or to explore our conformal coating offerings, please contact us and a member of our team will be glad to help.

Encapsulation

What is Encapsulation?

Encapsulation, also known as potting is the process of encasing the printed circuit board (PCB), or parts of it, in a resin. This protective resin serves multiple purposes, including shielding sensitive electronic components from environmental factors, enhancing durability, and improving resistance to mechanical stress.

Click here to view More Details

What is Encapsulation?

Encapsulation, also known as potting is the process of encasing the printed circuit board (PCB), or parts of it, in a resin. This protective resin serves multiple purposes, including shielding sensitive electronic components from environmental factors, enhancing durability, and improving resistance to mechanical stress.

Key Advantages Environmental Protection

Our advanced encapsulation: shields your PCB from moisture, dust, and other environmental elements, ensuring optimal performance even in challenging conditions.

Chemical Resistance: The protective resin provides resistance to chemicals, preventing damage from exposure to corrosive substances and enhancing the longevity of the PCB.

Vibration and Shock Absorption: Encapsulation acts as a buffer against vibrations and shocks, safeguarding delicate components from the mechanical stress that can occur during the PCB's lifecycle.

Improved Thermal Performance: Our encapsulation solutions contribute to better thermal management, dissipating heat efficiently and preventing overheating that could compromise the performance of your PCB.

Enhanced Reliability: By encapsulating your PCB, you enhance its overall reliability, reducing the risk of component failure and ensuring consistent functionality.

Why choose Pulsar Manufacturing?

We understand the critical role that encapsulation plays in the performance and longevity of your PCBs, our team are skilled and knowledgable and able to produce components to the toughest specification. Our strict quality regimes mean that standards like ATEX and UL are consistently met without compromise or question and our encapsulation process ensures that your product meets your innovation requirements, regardless of application conditions. To find out more, contact one of our friendly team today.

To find out more, contact one of our friendly team today.

Flow Soldering

What is Flow Soldering?

Flow Soldering, also known as wave soldering, is a crucial step in the PCB (Printed Circuit Board) manufacturing process. It is an automated soldering technique used to efficiently and reliably solder electronic components onto a PCB. This method is particularly suitable for through-hole components, which have leads that pass through holes in the PCB. Throughout the Wave Soldering process, the circuit board is passed over a bath of molten solder, where a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board.

Click here to view More Details

What is Flow Soldering?

Flow Soldering, also known as wave soldering, is a crucial step in the PCB (Printed Circuit Board) manufacturing process. It is an automated soldering technique used to efficiently and reliably solder electronic components onto a PCB. This method is particularly suitable for through-hole components, which have leads that pass through holes in the PCB. Throughout the Wave Soldering process, the circuit board is passed over a bath of molten solder, where a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board.

Advantages of Flow Soldering

Flow Soldering offers several advantages in PCB manufacturing, including speed, cost-effectiveness, and reliability. It is a well-established and widely used technique for high-volume production, especially for applications where through-hole components are predominant.

Chemical Resistance: The protective resin provides resistance to chemicals, preventing damage from exposure to corrosive substances and enhancing the longevity of the PCB.

Why choose Pulsar Manufacturing?

From the very beginning of the design process and prototype manufacture, right through to volume orders, the skilled and knowledgeable team at Pulsar Measurement are more than equipped to ensure your products are of the highest quality and utmost reliability. The Flow Solder technique, coupled with our rigorous and routine testing ensures that all products that come off the line at Pulsar Manufacturing go above and beyond the standard expectations of our customers.

If you would like to know more about our Flow Soldering services, please get in touch and our friendly team will be happy to help.

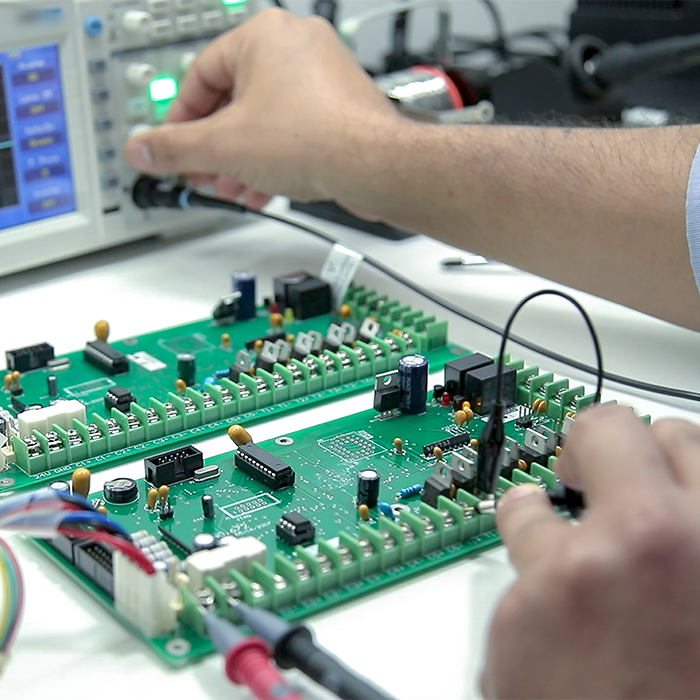

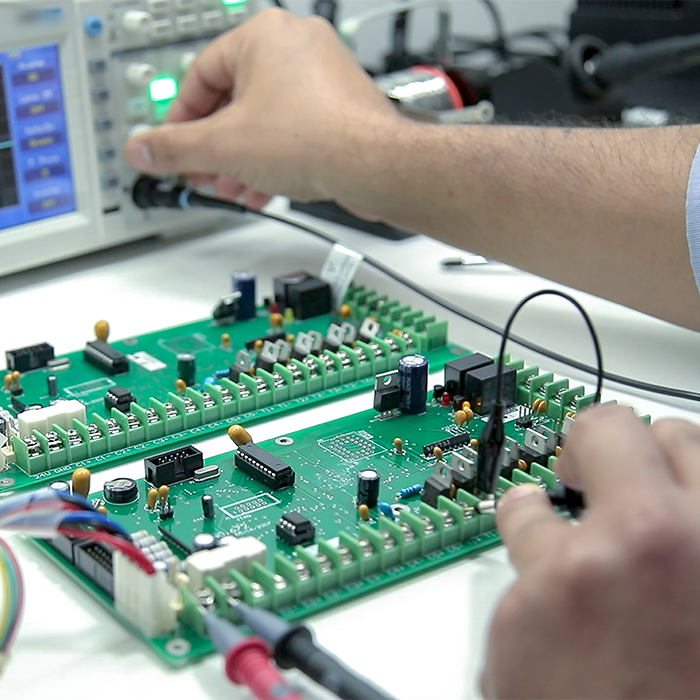

Functional Testing

What is Functional Testing?

At the heart of every electronic device lies a Printed Circuit Board (PCB), a complex interconnection of components that forms the backbone of functionality. Ensuring the reliability and functionality of these PCBs is paramount in today's rapidly evolving technological landscape. That's where the Functional Test in PCB Manufacturing becomes crucial.

Click here to view More Details

What is Functional Testing?

Functional Testing is a rigorous process employed in PCB manufacturing to verify that the assembled circuit board meets its design specifications and functions as intended. It goes beyond basic electrical testing by assessing the actual performance of the PCB under real-world conditions.

Advantages of Functional Testing

Ensures reliability: Functional testing ensures that the PCB functions reliably in real-world scenarios, reducing the risk of performance issues in the field.

Identifies Design Flaws: By simulating real-world usage, functional testing helps identify and rectify design flaws before the PCB goes into mass production.

Quality Assurance: Functional testing is a critical component of quality assurance in PCB manufacturing. It minimises the likelihood of fault PCBs reaching the end user

Enhances Product Lifecycle: Enhances Product Lifecycle: Rigorous functional testing contributes to the longevity of electronic devices by identifying and mitigating potential issues that could lead to premature failure.

Why choose Pulsar Manufacturing?

From the very beginning of the design stages right through to the final test, Pulsar Manufacturing's test and production engineers take the greatest care from start to finish and can use specially designed test software during the functional test, in order to ensure that all products leaving our factory are manufactured to the highest possible quality.

Printed Circuit Board Cleaning

What is Printed Circuit Board Cleaning?

The primary goal when cleaning PCB assemblies is to remove resin and flux residues. Although a 'no-clean' process is suitable for most industrial applications a further cleaning process is required for military, medical and aerospace.

Click here to view More Details

What is Printed Circuit Board Cleaning?

The primary goal when cleaning PCB assemblies is to remove resin and flux residues. Although a 'no-clean' process is suitable for most industrial applications a further cleaning process is required for military, medical and aerospace

Key Benefits

Enhanced Electrical Performance: Removal of contaminants ensures unimpeded electrical conductivity, minimising the risk of short circuits and electrical failures.

Improved Reliability: A clean PCB is a reliable PCB. Our cleaning solutions contribute to the overall reliability of your electronic devices, reducing the likelihood of malfunctions and failures.

Extended Lifespan: By eliminating harmful residues, our PCB cleaning services enhance the lifespan of your electronic components, ensuring sustained performance over time.

Optimized Thermal Management: Clean PCBs dissipate heat more effectively, contributing to improved thermal performance and preventing overheating issues.

Compliance with Industry Standards: Our cleaning processes adhere to the highest industry standards, ensuring that your PCBs meet and exceed regulatory requirements.

Why choose Pulsar Manufacturing?

Pulsar Manufacturing goes beyond industry standards to deliver excellence in PCB manufacturing and cleaning. We are committed to producing high-quality products, on time, and within budget. Being ATEX, UL, and ISO9001 certified holds us accountable for producing PCB products that meet the highest possible standard.

Contact our friendly team to find out more.

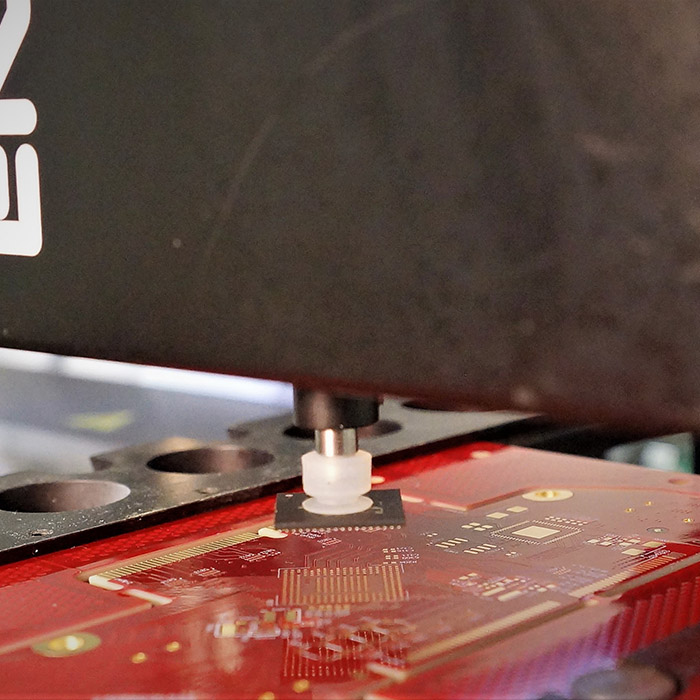

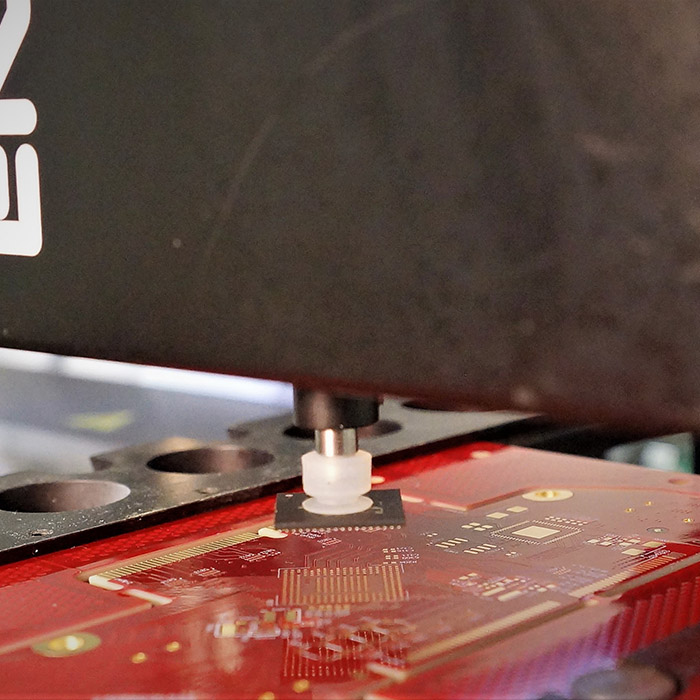

PCB Rework

What is PCB Rework?

PCB Rework is the meticulous process of repairing and modifying printed circuit boards that have undergone manufacturing or assembly issues. Whether it's correcting errors, replacing components, or enhancing existing designs, PCB rework is the key to salvaging valuable electronic assembles and ensuring they meet the highest standards of functionality and reliability.

Click here to view More Details

What is PCB Rework?

PCB Rework is the meticulous process of repairing and modifying printed circuit boards that have undergone manufacturing or assembly issues. Whether it's correcting errors, replacing components, or enhancing existing designs, PCB rework is the key to salvaging valuable electronic assembles and ensuring they meet the highest standards of functionality and reliability.

PCB Rework Advantages

Cost-Effective Solution: Instead of scrapping entire PCBs due to minor issues, PCB rework offers a cost-effective alternative, saving both time and resources.

Quick Turnaround: Reworking a PCB is often faster than manufacturing a new one, allowing for quick turnaround times and minimizing production delays.

Quick Turnaround: Reworking a PCB is often faster than manufacturing a new one, allowing for quick turnaround times and minimizing production delays.

Quick Turnaround: Reworking a PCB is often faster than manufacturing a new one, allowing for quick turnaround times and minimizing production delays.

Adaptability to Design Changes : PCB rework enables swift adaptation to design changes or component upgrades without the need for a complete redesign Environmental

Sustainability: Reworking reduces electronic waste by salvaging and improving existing PCBs, contributing to a more sustainable and eco-friendly approach to manufacturing.

Why choose Pulsar Manufacturing?

At Pulsar Manufacturing, we bring a wealth of experience and precision to every PCB rework project. Our skilled technicians and engineers leverage state-of-the-art equipment and techniques to ensure the highest quality standards in every rework endeavour. Want to hear more about our PCB rework processes? Get in touch and our team will be happy to help.

Contact our friendly team to find out more.

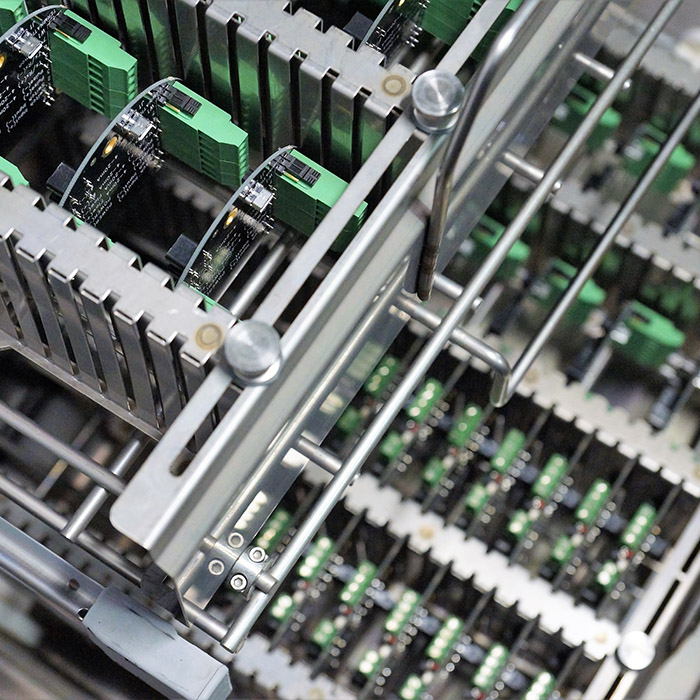

Surface Mount Technology (SMT)

What is Surface Mount Technology (SMT)?

Surface Mount Technology revolutionises PCB assembly by placing components directly onto the surface of the PCB, as opposed to through-hole technology that inserts components into drilled holes. SMT enhances the manufacturing process by optimizing space, reducing weight, and facilitating automated assembly techniques.

Click here to view More Details

How does SMT work?

The process generally starts with stencil preparation, which is a sheet of stainless steel that allows solder paste to be deposited in alignment with the component placement. Once the solder paste is in place and the stencil is removed, the components are placed by our automated pick-and-place machine. This process is extremely efficient and saves on production time when compared to manual hand placement.

Once the components are placed, the board is passed through a reflow soldering machine. This consists of a controlled heating environment within the machine, which melts the solder paste causing it to solidify so that solder joints are formed. Our specially trained technicians monitor the temperature to ensure the board is not damaged or poorly soldered. The final step is the inspection stage — we use AOI technology to ensure the boards we produce are inspected to the highest standard.

SMT Advantages

Space Efficiency: SMT allows for the placement of smaller, lighter components directly on the PCB surface, optimizing space and enabling the design of more compact and lightweight electronic devices.

High Component Density: The precision of SMT equipment enables the assembly of PCBs with high component density, allowing for intricate and feature-rich designs.

Automated Assembly: SMT is well suited for automated assembly processes, significantly reducing production time and costs while maintaining a high level of accuracy and consistency.

Improved Electrical Performance: SMT minimizes the length of electrical paths, reducing inductance and capacitance, and enhancing overall electrical performance.

Enhanced Thermal Performance: Direct component placement on the PCB surface promotes better heat dissipation, contributing to improved thermal management and preventing overheating issues.

Why choose Pulsar Manufacturing?

Pulsar Manufacturing can place components from 01005 packaged components, right through to the larger SMT packages with absolute precision to IPC-A-610 standards. The combination of our Surface Mount Technology and Automated Optical Inspection ensures that a high level of placement accuracy, solder joint integrity and quality is consistently achieved every time. State-of-the-art machines and technology allow up to 57,000 placements per hour and Pulsar Manufacturing are fully equipped to undertake PCB batches from low to high quantities. Still unsure if our SMT service is for you? Get in touch and one of our team will be glad to help.

Through-Hole Assembly

What is Through-Hole Assembly?

Through-hole assembly is a soldering technique employed in PCB manufacturing, primarily dedicated to securing electronic components with leads that traverse through holes in the PCB. This method ensures a strong mechanical and electrical connection, making it ideal for components requiring enhanced stability and durability.

Through-hole assembly finds its niche in a variety of applications, including automotive electronics, industrial controls, medical devices, and aerospace systems. In the ever-evolving landscape of PCB manufacturing, Through-Hole Assembly remains a steadfast technique, embodying the essence of reliability and strength. From classic applications to cutting-edge innovations, Through-Hole Assembly continues to shape the backbone of electronic connectivity, ensuring that each connection is a testament to precision and durability.

Click here to view More Details

What is Through-Hole Assembly?

Through-hole assembly is a soldering technique employed in PCB manufacturing, primarily dedicated to securing electronic components with leads that traverse through holes in the PCB. This method ensures a strong mechanical and electrical connection, making it ideal for components requiring enhanced stability and durability. Through-hole assembly finds its niche in a variety of applications, including automotive electronics, industrial controls, medical devices, and aerospace systems. In the ever-evolving landscape of PCB manufacturing, Through-Hole Assembly remains a steadfast technique, embodying the essence of reliability and strength. From classic applications to cutting-edge innovations, Through-Hole Assembly continues to shape the backbone of electronic connectivity, ensuring that each connection is a testament to precision and durability.

Advantages of Through-Hole Assembly

Mechanical Stability Through-hole assembly: Through-Hole Assembly Mechanical Stability Through-hole assembly provides exceptional mechanical stability, making it suitable for applications where components may undergo mechanical stress or vibration. This robust connection ensures the longevity of the PCB. Ease of Manual Repairs In the event of a faulty component, Through-Hole Assembly allows for relatively easy manual repairs or replacements. Technicians can desolder and replace individual components without the need for specialized equipment. High Current and Heat Resistance Components secured through Through-Hole Assembly can handle higher current loads and exhibit better resistance to heat compared to some surface-mount counterparts. This makes it a preferred choice for applications with demanding electrical requirements. Ideal for Prototyping Through-hole assembly is often favoured in prototyping and small-scale production runs. Its adaptability and ease of modification make it conducive to the iterative development process.

Why choose Pulsar Manufacturing?

With 25 years of industry experience, the team at Pulsar Manufacturing are highly skilled and knowledgeable, all workmanship is certified to IPC-610 standards, and all Inspectors and Production Engineers are IPC-A-610 certified specialists. Ensuring that your product is of the highest quality, every time. If you would like to know more about the Through-Hole Assembly services, please get in touch and our team will be happy to help.

Contact our friendly team to find out more.

X-Ray Inspection

What is X-Ray Inspection?

In the intricate world of printed circuit boards (PCBs), ensuring the quality and integrity of components is paramount. The X-Ray technique helps to provide unparalleled insight into the hidden realms of electronic connections. X-Ray provides an answer where you cannot optically see the solder connections, and gives PCB Manufacturers a method to examine the internal structures of PCBs without compromising their integrity.

Click here to view More Details

What is an X-Ray Inspection?

In the intricate world of printed circuit boards (PCBs), ensuring the quality and integrity of components is paramount. The X-Ray technique helps to provide unparalleled insight into the hidden realms of electronic connections. X-Ray provides an answer where you cannot optically see the solder connections, and gives PCB Manufacturers a method to examine the internal structures of PCBs without compromising their integrity.

Why is X-Ray inspection used?

X-ray inspection is instrumental in verifying the accurate placement of components, especially those with small form factors or intricate designs. This ensures that each solder joint is precisely where it should be, minimizing the risk of misalignments or defects. It allows manufacturers to detect any voids or inconsistencies that might affect the overall performance of the board. In multi-layer PCBs, ensuring proper layer-to-layer registration is crucial. X-ray inspection allows manufacturers to scrutinise the alignment of different layers, confirming that the vias and connections are accurately established. For PCBs with integrated circuits and semiconductor components, wire bonding is a critical process, X-ray inspection assists in detecting issues such as bond wire misalignment, bridging, or even wire breakage, ensuring the functionality and longevity of the integrated circuits.

Advantages of X-Ray Inspection

Advantages of X-Ray Inspection: Non-Destructive nature High precision and accuracy Efficiency in fault diagnosis Quality assurance

Why choose Pulsar Manufacturing?

The experienced team of test and production engineers at Pulsar Manufacturing allows for high-quality products and quick turnaround times. The X-Ray inspection process allows our engineers to ensure that the reflow of the solder joint is optimised for the leadless devices. Our main commitment at Pulsar Manufacturing is to help our customers with support and enhanced product quality for electronic components and Printed Circuit Board requirements. To find out more about our X-ray inspection process, get in touch today and our friendly team will be happy to help.

Contact our friendly team to find out more.

How to contact us

For any enquiries, please complete all fields in the form below and we will get back to you as soon as possible.

Prefer to call? We're happy to help.

Phone: +44 (0) 1787 478771

Downloads Centre

Access technical datasheets, product manuals, compliance certificates, safety guidelines, and more all in one centralised location.