Flow Measurement of a Copper Mine in Jiangsu, China

Copper mining is a complicated process that begins with the mining of the ore that is found within the earth’s crust and ends with sheets of pure copper, which ultimately will be made into products for everyday use.

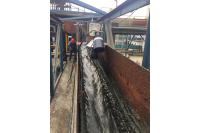

A copper mine that is based and operates out of the Jiangsu Province in China required open channel flow measurement for 15% - 20% refined copper pulp. This means that there was a high number of solid particles flowing through the medium, these solid particles have a high concentration and can easily stick to the pipe wall.

flowing through the medium, these solid particles have a high concentration and can easily stick to the pipe wall.

Finding the right flow measurement solution

It was decided that the best place to monitor would be the U-shaped groove that flows into the thickener, as the mine did not have space to install weirs and troughs and the conditions of the application were too harsh for doppler ultrasonic flow sensors.

After a few site visits and an analysis of the application, it was decided that the MicroFlow non-contacting velocity sensors would be the best choice. A set of MicroFlow non-contacting velocity sensors were installed over three years ago, with the goal of helping the mine to optimize its process flow.

Success with MircoFlow Velocity Sensors

The flow data received from the MicroFlow velocity sensors provide flow readings that are consistent with the actual flow through field process verification. Even with the high solid particles that flow through the liquid, the MicroFlow can provide information that helps the Copper Mine to optimize its process and ensure that things are running as smoothly as possible.