Discontinued Products

These products are no longer sold.

The AVFM 5.0 Area-Velocity Flow Meter measures both Level and Velocity to calculate flow in an open channel, partially full sewer pipes, and surcharged pipes without a flume or weir. Calibration is simple: enter the pipe diameter or channel dimensions and the AVFM 5.0 automatically computes and displays flow volume.

The AVFM 5.0 has been replaced by the AVFM 6.1 Area-Velocity Flow Meter, which offers enhanced performance and optional Modbus RTU Output.

The Blackbox blind non-isolated version was designed for anyone who needed a simple straight forward level indication. With no display, it was ideal for those applications where power was scarce and it could be programmed via a handheld calibrator or Blackbox PC Software.

The unit has now been replaced by the Blackbox 130 display version, which can be programmed via its integral keyboard and provides an output representative of volume.

The Blackbox 130 was a compact, non-contacting level controller designed to deliver simple and reliable level measurement.

It featured a built-in display, 4–20mA output, and alarm relays for straightforward integration with existing site systems.

As an alternative, we recommend the Ultra 4, available in wall and fascia mount options, same outer dimensions, all the features of the Blackbox plus: MCERTS Class 1 certified, 4 programmable relays, SD card data logging, pump control, flow measurement and more.

| Name | Content | Download |

|---|---|---|

| Blackbox 130 | Diesel Tank Monitoring | Download |

| Blackbox | Display of a blackbox-panel | Download |

| Blackbox 130 | Download | |

| Blackbox 130 | Product Brochure | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| Blackbox 130 | Datasheet | Download |

| Blackbox 130 | Installation & Instruction Manual | Download |

| Blackbox 130 | Installation & Instruction Manual - UL | Download |

| Blackbox 130 | Technical Drawing (UNCONTROLLED COPIES) | Download |

| Blackbox CSO Log | Blackbox CSO Log Software | Download |

| Blackbox 130 Firmware | Version 2.1.3 | Download |

| BlackBox 130 | Case Study | Blackbox provides Combined Sewer Overflow monitoring for Slovenia | Download |

| Blackbox 130 | Case Study | Blackbox provides height alarm for hydraulic excavator. | Download |

| BlackBox 130 | Case Study | BlackBox 130 sucessfully measures stone in a difficult dusty environment. | Download |

| PC Suite | Ask the Expert | Marc Richards on PC Suite | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

The DFM 5.1 Doppler Flow Meter monitors the flow rate of dirty or aerated liquids including wastewater, chemicals, acids, slurries, abrasives, and viscous liquids. Recommended for full pipes and any fluid that contains solids or bubbles. The sensor is mounted on the outside of a plastic or metal pipe 12.7 mm (0.5 in) diameter or larger.

The DFM 5.1 has been replaced by the DFM 6.1 Doppler Flowmeter, which offers enhanced performance and now has as an option Modbus RTU or HART.

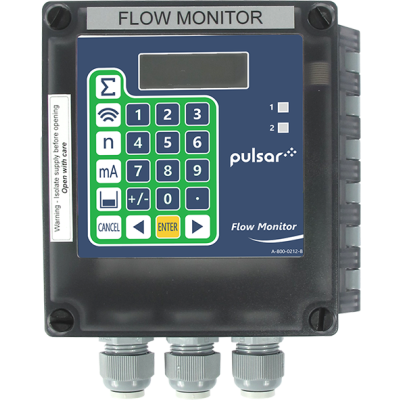

The Flow Monitor was designed to be combined with the FlowPulse Sensor, a dedicated wall-mounted device that gives an instant indication to pipe flow.

The unit is ideal for fixed installations that require constant pipe flow measurement

As an alternative, we recommend the DFM 6.1, which offers enhanced performance and functionality.

| Name | Content | Download |

|---|---|---|

| Flow Monitor | Download | |

| Flow Monitor Firmware | Version 1.0.8 | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| Flow Monitor | Datasheet | Download |

| Flow Monitor | Installation & Instruction Manual | Download |

| Flow Monitor | Technical Drawing (UNCONTROLLED COPIES) | Download |

| UltraLog Software Manual | UltraLog Software Manual | Download |

| FlowPulse | FlowPulse was able to restore flow monitoring to a pump station quickly, without the need for expensive in-line flow monitoring. | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

The ISM 5.0 Electromagnetic Flow Meter is an accurate, low-cost insertion mag flow meter alternative to full-bore mag flow meters. Measure the flow of water and conductive liquids in full pipes from 80 mm to 1800 mm (3 in to 72 in) diameter.

The ISM 5.0 dual pair electrode sensor inserts through a tap in the pipe wall. It can be easily installed in new pipe systems or by a hot tap in pressurized pipes with flowing liquids. There are no moving parts so obstruction to flow and pressure drop is minimal. Installation through a full port ball valve allows easy retraction and reinsertion without shutting down flow. The dual-electrode sensor and continuous auto-zero function provide high accuracy – even at low flow rates. State-of-the-art electronics and patented design features help maintain its NIST traceable accuracy over time.

To find out more about our ISM 5.0 insertion magmeter, contact us today.

The Greyline OCF 5.0 uses a non-contacting ultrasonic sensor mounted over a flume or weir to measure flow. It is accurate, reliable, and verifiable. The separate, watertight electronics/display enclosure can be mounted within 150 m (500 ft) of the sensor. The OCF 5.0 continuously displays, totalizes, transmits and data logs open channel flow.

The Greyline OCF 5.0 Open Channel Flow Monitor has been replaced by the Greyline OCF 6.1 Open Channel Flow & Tank Level Meter, which offers expanded flume & weir selections or level tank monitoring, and it also has optional MODBUS RTU Output.

The PDFM 5.1 Portable Doppler Flow Meter is a portable flow meter that clamps to the outside of a pipe to gain pipe flow measurement. The ultrasonic Doppler technology used by the PDFM 5.1 makes it perfect for use as a water flow meter, specifically for dirty or difficult liquids that contain bubbles or solids, like wastewater, slurries, sludge, chemicals, viscous liquids, and abrasives.

The PDFM 5.1 is ideal for evaluating system performance and can be installed, calibrated, and started up in minutes. Use this flow meter where a permanent flow meter is not required, or temporarily replace installed flow meters. Fast and easy to operate, the sensor mounts to the outside of a pipe in less than a minute, using the built-in keypad and calibration menu to set up the flowmeter for the application.

With its internal battery, the PDFM 5.1 will operate all day and recharge overnight. For continuous use, it can be powered by a supplied 110-240 V AC wall plug adaptor or use Sleep Mode to only wake up the meter to take a measurement periodically, extending battery life. A 300,000-point data logger is built into the unit.

Display units can be selected by the user, and the PDFM 5.1 Portable Doppler Flow Meter will display and totalize flow in gallons, liters, cubic feet, or cubic meters. If you change from one measurement system to another, the PDFM 5.1 will automatically and instantly calculate and covert the total flow display and totalizer. Calibrate to the pipe size using the keypad to enter the inside diameter.

The 4-20mA output featured on the unit allows you to use the PDFM 5.1 Portable Doppler Flow Meter in critical applications. Ideal applications for this ultrasonic flow meter, with a non-contacting clamp-on ultrasonic sensor include influent and effluent pipe flow, industrial pipe flows, irrigation flows, food and beverage manufacturers, pharmaceutical processes, and many more!

Gain a full overview of our pipe flow measurement solutions by contacting a member of our team today.

Gain a full overview of our pipe flow measurement solutions by contacting one of our team today.

| Name | Content | Download |

|---|---|---|

| PDFM 5.1 | Sand slurry measurement with PDFM 5.1 | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| PDFM 5.1 | Installation & Instruction Manual | Download |

| PDFM 5.1 | Engineering Specifications | Download |

| Pulsar Logger | Pulsar Logger v3.0.0 Software (Formerly Greyline Logger) | Download |

| Greyline Logger | Software Brochure | Download |

| Two Technologies for Flow | Doppler and Transit Time for non-invasive measurement of flow in full pipes. | Download |

| Doppler for Fly Ash Slurry Flow | The limestone slurry is abrasive so in-line flowmeters are not practical. Non-contacting Doppler flowmeters can be used both on the fly ash slurry supply lines and on "used" or recirculated slurry. | Download |

| Explosion Proof Enclosure | Datasheet | Explosion Proof Enclosure | Download |

| SCR Enclosure Sun Screen | Datasheet | SCR Enclosure Sun Screen | Download |

| Stingray, PDFM, DFM | Case Study | Portable flow meters solve flow rate discrepancies between pump station effluent and lagoon influent flow meters. | Download |

The PTFM 1.0 Portable Transit-Time Flow Meter measures pipe flow with a clamp-on, non-contacting, ultrasonic sensor. Measuring the time it takes to transmit one ultrasonic sound from one sensor to the other. The Portable Transit-Time Flow Meter can be used for calibrations, troubleshooting, flow surveys, or as a temporary clamp-on flow meter to replace inline flowmeters. Causing no interruption to the process, no downtime, and no need to cut into a pipe, simply strap the transit-time sensors to the outside of the pipe from 50 mm to 1200 mm (2 in to 48 in) diameter.

The transit-time technology makes the PTFM ideal for clean liquid flow monitoring on applications such as treated water flow, effluent pipe flow, irrigation flow, and compliance with water abstraction licenses.

The PTFM 1.0 Portable Transit-Time Flow Meter can be mounted without interrupting operations and there is no obstruction or pressure drop. With no moving parts, there is little to no maintenance required with the PTFM 1.0, and the unit gives accurate and repeatable pipe flow readings for clean liquids in minutes.

The PTFM 1.0 has now been replaced by the upgraded PTFM 6.1 version which can be viewed here

| Name | Content | Download |

|---|---|---|

| TTFM 6.1 | Summerheights Golf Links Ontario, get efficient control over water pumped to sprinkler system | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| PTFM 1.0 - Discontinued | Installation & Instruction Manual | Download |

| Pulsar Logger | Pulsar Logger v3.0.0 Software (Formerly Greyline Logger) | Download |

| Greyline Logger | Software Brochure | Download |

| Two Technologies for Flow | Doppler and Transit Time for non-invasive measurement of flow in full pipes. | Download |

| Explosion Proof Enclosure | Datasheet | Explosion Proof Enclosure | Download |

| SCR Enclosure Sun Screen | Datasheet | SCR Enclosure Sun Screen | Download |

| PTFM 1.0 - Discontinued | Datasheet | Download |

The PulsarGuard 2001 sand sensor has been specifically designed for the Oil and Gas industry, using acoustic technology to detect sand / solids impact rate. The non-contacting sand-in-oil sensor is connected to the outside of the pipeline with a stainless steel band, meaning there is no need to break into the pipe or interrupt the operation. Using acoustic technology, it detects changes in the signature of flow within the pipe and converts it into a sand / solids impact rate. This makes it the ideal sensor to monitor well productivity and efficiency, detect blockages and/or foreign objects, and monitor the production of sand in oil and gas operations.

The PulsarGuard 2001 sand sensor MUST be used with the iSensys SandAlert monitor or the iSensys SandAlert portable units. The oil sensor is an intrinsically safe unit, ATEX approved to ATEX EEx ia IIC T4, and is made from 316 stainless steel with environmental protection to IP68. Its narrow frequency band makes the sensor highly resistant to interference from background noise, fluid flow, or gas flow.

For more information on our Sand in Oil measurement products, contact one of our friendly team today.

| Name | Content | Download |

|---|---|---|

| PulsarGuard 2001 | Download | |

| PulsarGuard 2001 | Product Brochure | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| PulsarGuard 2001 | Datasheet | Download |

| PulsarGuard 2001 | Installation & Instruction Manual | Download |

| ATEX PulsarGuard 2001 | Ex ia Certificate | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

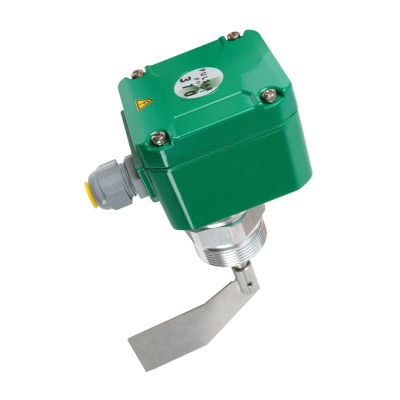

The PulsarPoint 300 series provides effective management of material storage and flow, empty vessels, clogged or blocked chutes or conveyors, and provides prevention of overflows. The ideal applications for this product are usually found in food and beverage, animal feed, pharmaceutical, chemical, plastics, quarrying, power generation, cement, and other industrial-like industries. They are perfect for those applications that require accurate level measurement of solids.

The PulsarPoint 300 series uses a rotating paddle, the paddle's rotation is interrupted when the material reaches the paddle, causing a clutch to disengage the motor. This in turn actuates a relay allowing an alarm signal to be switched. The product is fully configurable and can be used to signify high, intermediate, or low-level material.

| Name | Content | Download |

|---|---|---|

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

Specifically developed for sand monitoring in the oil and gas industry, the iSensys SandAlert monitor is a sand and particle monitor that is ideal wherever you need to keep wells producing efficiently. Sand production for oil and gas operators is an increasing problem and can cause catastrophic damage to well and rig equipment. The SandAlert provides robust, dependable sand monitoring data, so plant operators can be confident they are operating at the highest capacity possible.

Why Measure Sand in Oil?

Solids/sand production in oil and gas wells is a growing problem for oil and gas producers. Over the ages, there is a tendency to produce more solids through reservoir degradation. The challenge is not only to avoid solids/sand production but also to optimize well productivity, as even small quantities of solid particles in the well flow can cause significant pipe or valve damage.

When solids or sand are produced from a reservoir, the production rate is reduced, and maintenance costs go up. It also represents an environmental risk in the disposal of the solids. Produced solids/sand can never be ignored, and any well producing from an unconsolidated reservoir needs to have some sort of sand monitoring system in place, preferably monitoring in real-time.

The iSensys SandAlert monitor is designed to provide plant operators with the data they need on sand/solid production so that site and asset maintenance and management can become predictive and effective. The SandAlert system can measure sand production directly, without external or additional flow measurement.

When used with the PulsarGuard 2001 sand sensor, the unit can be positioned up to 1,000 m (3,280 ft) away from the application. An optional explosion-proof case is available for the SandAlert that converts the system into one that can be fully installed in a Zone 1 hazardous area. The graphical display shows a general overview of current signal information, a real-time sand impact trace graph, and an overview of relay settings.

To find out more about sand in oil monitoring, contact one of our friendly teams today.

| Name | Content | Download |

|---|---|---|

| iSensys SandAlert | Monitor | Download |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| SandAlert Lite | Installation & Instruction Manual | Download |

| SandAlert Wall Mount | Installation & Instruction Manual | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

Sand monitoring in the oil and gas industry is absolutely paramount to keep wells producing efficiently and at capacity. Excessive solid production in the oil stream can cause catastrophic damage to well and rig equipment. The iSensys SandAlert Portable Sand Monitor has been designed to give oil and gas producers robust and dependable sand monitoring solutions. The Portable Sand Monitor is fitted into a rugged pelican case and is a complete kit including sensor, mounting strap, and 50 m extension lead, ideal for transporting between multiple sites.

When sand is produced from a reservoir, the production rate is reduced and maintenance costs go up, it also presents environmental risks with disposal of the solids. Produced sand enters the processing system and plant operators need to make sure that the process is capable of handling the sand/solids safely. An important aspect of sand management is reviewing erosion rates and removal issues.

The high-frequency, structure-borne acoustic signal generated by a sand impact on the wall of the pipe is detected by the PulsarGuard 2001 Sand Sensor. The acoustic signal is then converted and displayed on a graphic display on the iSensys Sand Alert Portable Sand Monitor.

For more information on our sand monitoring equipment, contact one of our friendly team today.

| Name | Content | Download |

|---|---|---|

| PulsarGuard 2001 | Download | |

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| SandAlert Lite | Installation & Instruction Manual | Download |

| SandAlert Portable | Installation & Instruction Manual | Download |

| PulsarGuard 2001 | Installation & Instruction Manual | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

The SLT 5.0 Level & Flow Monitor, displays, transmits, and totalizes wastewater flow through any flume or weir. Each SLT 5.0 includes a non-contacting ultrasonic sensor that mounts above the liquid being measured. Select flow mode for open channel applications or level mode for tank inventory, level control, and alarms.

The SLT 5.0 Level & Flow Monitor, has been replaced by the OCF 6.1 Open Channel Flow & Tank Level Meter, which offers expanded flume & weir selections or level tank monitoring and it also has optional MODBUS RTU or HART Output.

| Name | Content | Download |

|---|---|---|

| (ALL) Pulsar Product Brochures | All brochures in one .zip folder | Download |

| SLT 5.0 - Discontinued | Installation & Instruction Manual | Download |

| SLT 5.0 - Discontinued | Engineering Specifications | Download |

| SCR Enclosure Sun Screen | Datasheet | SCR Enclosure Sun Screen | Download |

| SP1 Surge Protection | Datasheet | SP1 Surge Protection | Download |

| Warranty | Pulsar Measurement Product Warranty | Download |

The TTFM 1.0 Transit Time Flow Meter is designed for flow measurement of fairly clean, nonaerated liquids in full pipes. The clamp-on transducers can be mounted without system shutdown. There is no pressure drop and no obstruction.

The TTFM 1.0 has been replaced by the TTFM 6.1 Transit Time flowmeter, which now offers pipe sizes as low as 12.7 mm to 1.2 m (0.5 in to 48 in) and has optional Modbus RTU or HART.

Ultra 3 combines several full-function, world-beating ultrasonic level measurement instruments into one. Full control functions are available: open channel flow is calculated to BS ISO 1438 and 4359. Pump Control features are built into Ultra 3 and an extensive set of volume calculations and linearisation facilities are available for a tank or silo level measurement task.

The Ultra 3 has been replaced by the Ultra 4 which offers the extra relay and the ability to combine three specific duties in one compact and cost-effective control package.