DFM 6.1 Provides Volumetric Measurement for Thai Cement Column Company

The production and consumption of cement is largely concentrated in Asia, accounting for 73% of the output globally and a consumption of 81%. The Thai Cement Column Company were looking for flow rate and volume measurement of high-pressure cement slurry which is used for cement injection in soil cement columns, often referred to as Jet Grouting.

What is Jet Grouting?

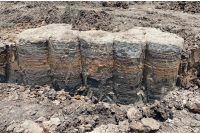

Jet grouting uses high-velocity fluid jets to construct cemented soil of varying geometries in the ground. It’s often the preferred solution in any situation requiring control of groundwater, or excavation of unstable soil, and can be used to underpin foundations such as quay walls and heavy structures, provide excavation support, or to seal the bottom of planned excavations.

The Jet Grouting Process

Jet Grouting creates in-situ columns of grouted soil, using a grouting monitor attached to the end of a drill stem. Then high velocity jets (cement grout with optional water and air) are initiated from ports in the monitor. The jets erode and mix the in-situ soil with grout as the drill stem and monitor are rotated and raised.

Challenges of Flow Measurement

The Thai Cement Column Company didn’t have a way of reporting back to their customer about their flow rate and the volumes of cement that they were using. When it came to choosing a flow measurement solution, inline flow meters were unsuitable as the high velocities of the Jet Grouting process would have damaged flowmeters that sit inside the pipe.

Thai Cement Column Company reached out to Intech 2000, Pulsar Measurement’s partner in Thailand for help. After looking at the application, Sales Engineer Narongdech Nalumpoom of Intech 2000 suggested the DFM 6.1 Doppler Flow Meter.

Success for the DFM 6.1

Because of the nature of the measurement substance and high velocities, the DFM 6.1 was chosen as the non-contacting flowmeter of choice. The DFM 6.1 Doppler Flow Meter uses Doppler technology, making it ideal for difficult liquids or liquids with suspended solids, such as cement slurry. The sensor is simply clamped and secured to the outside of the pipe and an acoustic signal is reflected back to the sensor from moving particles or gas bubbles suspended in the fluid.

Before installing the DFM 6.1, the customer was calculating the volume of cement slurry from the length of a pump cycle alone, which was proving to be inaccurate. The installation of the DFM 6.1 was a success and the customer can now accurately and reliably measure the efficiency of the Jet Grouting applications.

Making Installation a Breeze

Because of the simplistic 5-button menu system, the customer was able to set up and install the DFM 6.1, with some guidance and suggestions on first time parameter entry from Intech 2000, in just a few minutes. As a result, the customer can make a much more accurate calculation of the volume of their cement slurry.

Click here for more information on the DFM 6.1 Doppler Flow Meter.

Click here to find a local partner in your region.